Warehouse storage in Europe

Whether you have a small or a medium-sized online store, your products need to be stored somewhere. Setting up or organizing your warehouse in an efficient way is very important. An optimized ecommerce storage makes it easier to grow your business when you receive more orders. Here you will find out more about setting up an efficient storage solution for your ecommerce business.

The biggest mistake that ecommerce businesses often make when they set up their warehouse is: thinking of it as a big box where they can store items. Yes, it is a storage space, but an efficient ecommerce storage solution takes more than just storing items. You will also need to track each item, be able to move them and prepare them to be shipped.

The biggest mistake that ecommerce businesses often make when they set up their warehouse is: thinking of it as a big box where they can store items. Yes, it is a storage space, but an efficient ecommerce storage solution takes more than just storing items. You will also need to track each item, be able to move them and prepare them to be shipped.

Content

- Organizing your warehouse storage

- The right storage shelves

- Smaller aisles?

- The different areas in a warehouse

- FAQ

Organizing your warehouse storage

When you are organizing your warehouse storage solution, try and keep in mind that there should be room for an uninterrupted flow of goods at any time. Items will pass by in all different areas of your warehouse space, whether it’s the receiving zone, the storage shelves, the picking route or the packing stations.

The most important part about storing items is that they need to be shipped. The shipping process need to happen efficiently. Keep that in mind and you will be able to design your warehouse space. Next to the right warehouse management system you need to make good use of the storage space.

Keep in mind that your items need to be shipped easily.

Looking to outsource your fulfillment? Salesupply and ShipBob are fulfillment partners with multiple European warehouse locations, making it possible to offer next day delivery all over Europe.

It could save you a lot of time and money

Creating warehouse storage solutions can be very rewarding. Not only in terms of capacity, but also in terms of efficiency. If you process many orders every day, you are probably spending several hours per day on order picking, packing, and shipping.

Creating warehouse storage solutions can be very rewarding. Not only in terms of capacity, but also in terms of efficiency. If you process many orders every day, you are probably spending several hours per day on order picking, packing, and shipping.

Gaining even ten percent of that time would yield enormous savings. Furthermore, setting up your warehouse the right way also reduces physical complaints, which improves workplace atmosphere.

When the amount of orders grows, efficient warehouse storage can save you a lot of time.

Ecommerce warehousing companies in Europe

While you can save money with an efficient ecommerce warehouse, it could become a problem once your store grows. Larger ecommerce businesses invest in multiple warehouse locations an inventory management software, to create a constant flow of products going in and out.

These costs can add up quickly. That is why some ecommerce companies decide to use storage services from a storage company, like logistics providers or fulfillment companies. These have storage units available and will take care of order picking , inventory management and shipping.

The right ecommerce storage systems

Online retailers who started their online shop out of their basement or garage, are probably familiar with the following situation. After putting up a shelf, they find out that they need more storage space. This results in cramming, losing track of items and, overall, one big mess. Maybe you have found someplace to set up a second racking system, but now you have less room to walk around freely while picking your items.

Online retailers who started their online shop out of their basement or garage, are probably familiar with the following situation. After putting up a shelf, they find out that they need more storage space. This results in cramming, losing track of items and, overall, one big mess. Maybe you have found someplace to set up a second racking system, but now you have less room to walk around freely while picking your items.

Before buying warehouse racking systems, be aware of the size of your products.

There is a wide range of storage systems, like mezzanine floors or racking systems. Before you start buying them, be aware of the size of your items and adjust your storage systems accordingly. Some products may be larger, make sure that these cardboard boxes do not take up space of your walking aisles. That could lead to some dangerous situations for you or your workers!

Smaller aisles?

So how do you create more storage space in your warehouse? The smaller the aisles between the shelves, the bigger the actual storage capacity of your warehouse. You could make your aisles a bit smaller to add more warehouse racking systems.

So how do you create more storage space in your warehouse? The smaller the aisles between the shelves, the bigger the actual storage capacity of your warehouse. You could make your aisles a bit smaller to add more warehouse racking systems.

However, be careful to not make them too small! If you get more stock, you will want multiple picking carts, or even a forklift to fit in there. It will be a lot of work to have to reorganize all your racking systems to widen your aisles again.

Different areas in a warehouse

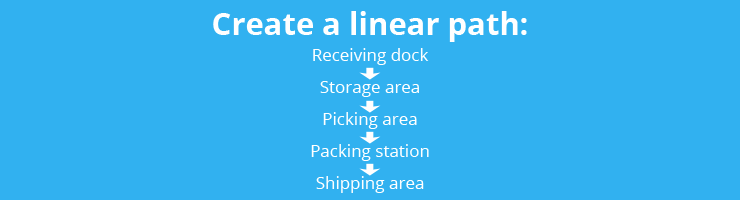

An efficient warehouse space consists of different areas. It’s not just about storing and picking your items, they also need to be packed, right? And what about getting them in or out of your warehouse? When designing your warehouse floor plan, keep this in mind. Infoplus has made a nice design for a small business warehouse layout:

As you can see in the image above, this fictional warehouse space is divided into 7 different areas: the receiving staging area, the storage picking area, the packing station, the shipping area, the ship staging area, the office space and free area. When you are designing the best flexible warehouse space, keep these different areas in mind and their purpose.

The receiving area

This is the area where you receive your items. Smaller warehouses often have a single dock for both shipping and receiving. This isn’t very efficient, as this will result in items piling up in your shipping area.

This is the area where you receive your items. Smaller warehouses often have a single dock for both shipping and receiving. This isn’t very efficient, as this will result in items piling up in your shipping area.

Whenever you receive your goods, immediately put them into a receiving area. Keep this part of the warehouse space separate from order fulfillment and shipping.

Storage and picking area

The storage area is where you find storage systems to store you items. It is also where you can pick them whenever they are ready to be shipped. This means that you need to establish a clear and efficient route for your workers. Items that are ordered quite often (the so-called high-velocity orders) should be easily accessed.

Put your most popular products close to your packing station.

Think about putting them in the front of your storage space and/or as close to your packing station as possible, so the travel time is minimized. Less popular items can be kept in a larger bulk storage area somewhere in the back.

The packing station

You should also create a designated area where you can pack items. While thinking of a good place to put the packing station, try to design it so that goods can come in at one end and finished packages come out the other. Think of the order “pick, pack, ship”. Pickers bring the items to the packing station, where the goods get packed so they can get shipped away.

You should also create a designated area where you can pack items. While thinking of a good place to put the packing station, try to design it so that goods can come in at one end and finished packages come out the other. Think of the order “pick, pack, ship”. Pickers bring the items to the packing station, where the goods get packed so they can get shipped away.

The shipping area

You should also have a separate area for shipping items, because you need to be able to send a parcel to its customer. Once an item has been packed and has the correct shipping label, set it aside. This creates more space in your packing station and makes it easier for parcel couriers to find them.

Free space

This will (likely) create some free space that you are not using yet. Do not think of it as useless, because it can still be useful! You could use it to create easy access for your workers and machines. It could also be used to generate more space between the receiving and shipping areas. If your online store grows even more, you could give up this free area and turn it into something else, like an extra packing and shipping station, or an extended area for your high-velocity orders.

Frequently Asked Questions

Here are some frequently asked questions about setting up and organizing your warehouse storage space:

How much does warehouse storage cost?

Many online retailers want to know how much warehouse storage systems cost. There is no simple answer to this, as it differs per situation.

You will pay more if your warehouse is at an “A”-location and if it’s in a major city. The rule of thumb for warehouse storage costs is 75 euros per square meter. Here is a list of how much warehouse storage costs in different cities across Europe.

Warehouse storage costs = €75 per m²

The most expensive areas for renting warehouses in Europe are in the United Kingdom, Norway, Finland and Germany. For example, in London Heathrow you pay 215 euros per square meter per year, while in the Polish city of Poznan you only pay 41 euros. That’s also why most major online retailers have their distribution centers and warehouses located in European countries such as Poland.

Ecommerce warehousing is cheaper in Poland.

Why use a warehouse if there's dropshipping?

Dropshipping is a very popular business method for online retailers. It enables them to sell products, without having to worry about storing, picking, and shipping the items. Whether it is the right solution to go for warehouse storage or dropshipping, depends on your ecommerce business.

With your own warehouse, you will have better stock control.

If you go for warehouse storage, you can see your stock and thus have better inventory management or stock control.

That way, you can check out new products yourself to see if the quality meets your standards. You can make product photos or try the items out, so that you will be able to answer questions from your customers.

How do you calculate warehouse storage capacity?

In warehouses, space is your most valuable asset. It is important to make the best use of your available warehouse space. You will need space for aisles, but also do not forget bathrooms or offices.

Furthermore, do not just think in square meters. There is even more space when you build upwards with racking systems, for example! To calculate your warehouse’s storage capacity you will need to use cubic meters.

Use cubic meters to calculate your storage capacity.

Take the number of square meters that are available, subtract the square meters you can not use from this and then multiply it with the height in meters you can use.